Earthlings' Coffee Farm Trip to Bario and Long Banga

Here's a record of our recent coffee trip to Bario and Long Banga, along with my thoughts on the current coffee situation in rural Sarawak. If there's any disagreeable content, please feel free to comment.

This trip was long overdue at Mr Alasdair Clayre's third invitation. Alasdair is an Anthropology PhD candidate at UNIMAS who has a special connection to Long Banga and wanted us to help the coffee farmers in the area. He is a Borneo-born caucasian who returned to Britain at a young age, went to Cambridge University, and came back to Long Banga to continue his research. The villagers here treat him as one of their own. He said his parents were missionaries who came to the mountains to preach.

I have been paying attention to the coffee issues in the Sarawak highlands for a long time. Besides our collaboration with the Lawas Coffee Estate, we have also received many coffee samples brought by other villagers from the highlands. This trip was just a continuation of our efforts for the past few years.

Because transportation presented significant challenges, embarking on this journey was not a simple feat. In anticipation of ascending the mountain, I privately reflected on past difficulties, scrutinised the quality concerns surrounding the local coffee, and prepared a few solutions aimed at addressing key issues. These included strategies for helping local coffee farmers understand better the coffees they are growing, resolving the frequent issue of mould, ensuring that farmers' income provided sufficient incentive for continued farming, and finding ways to tackle the transportation difficulties inherent in reaching Long Banga, a location that is a 22-hour drive from Kuching.

To avoid a fruitless journey, priority must be given to solving the above problems. From my observation, we should first set up a few successful cases where existing coffee farmers could sell their coffee at an ideal price. This would help build confidence and gain interest from other farmers.

Of course, there are more specific issues on the farmers' end that need to be addressed. I remembered that Jackz from Sabarica said that he is eager to join any trip to the Sarawak highlands, so I got him on board. Sabarica has been presenting the best Arabica in Malaysia over recent years, Jackz undoubtedly possesses valuable experience that local farmers can learn from.

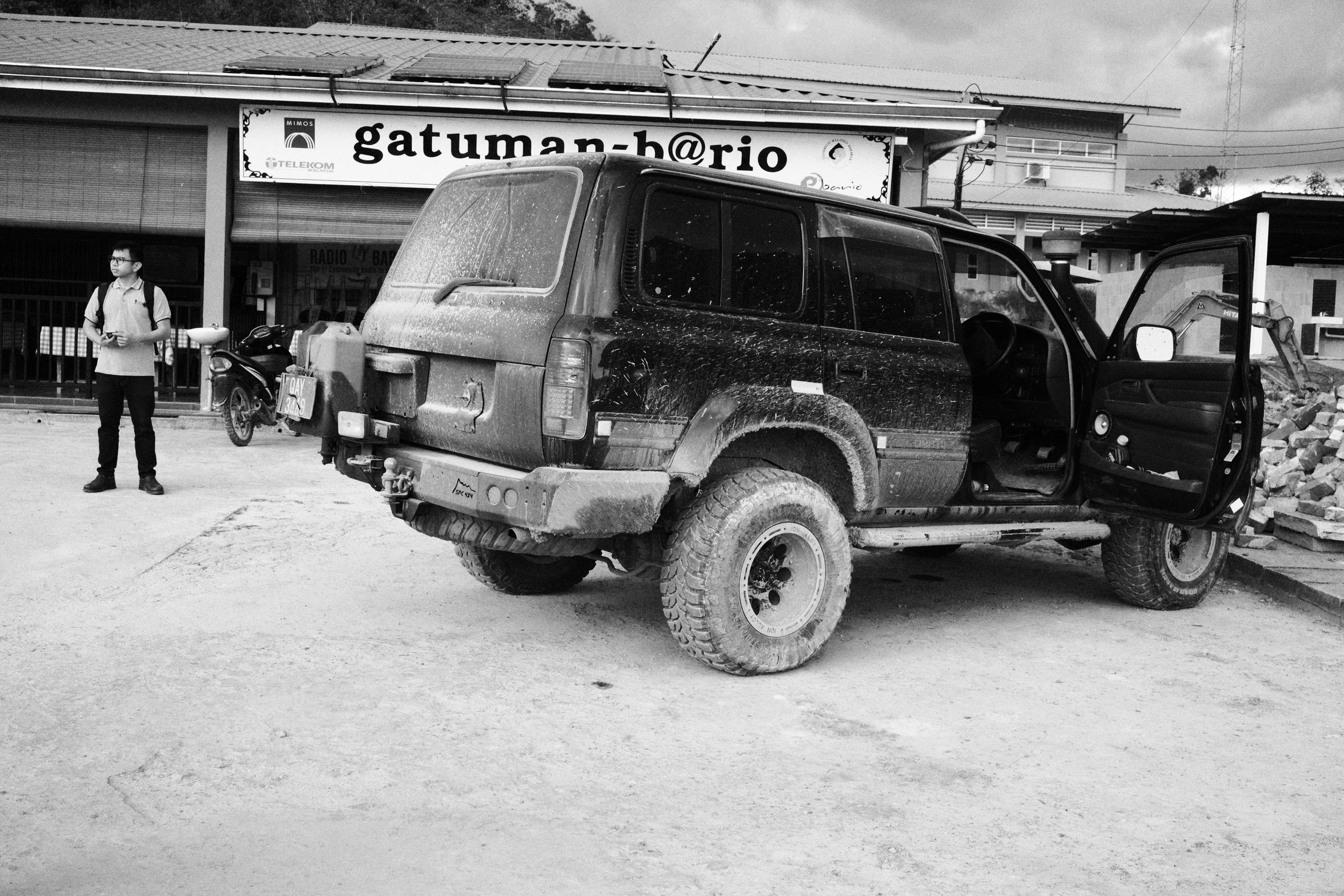

We first flew to Miri, and from Miri to Bario Highlands. We stayed for the night at Rumah Asal, which was generously sponsored by Dr Roland Mattu. The next day we departed for Long Banga by car. We stopped by Pa Dali and Pa Dallih on our way. It was such a bumpy ride through muddy grounds which can hardly be called a "road" after heavy rain. We went up and down the mountains and finally reached Long Banga early evening.

During this four-day trip, we visited eight coffee farms. Seven of which planted mainly Liberica and its variants, with a few sporadic Canephora (Robusta) in some of the farms. Only one nursery owned by Dr Roland Mattu's family in Bario Highlands has some Arabica trees and seedlings.

What surprised us was that most coffee farmers in the Long Banga area seem to be unaware of what species of coffee they are growing. Many farmers told us they think they are growing a particularly large and fine variety of Arabica. In fact, out of the five plantations we visited in Long Banga, we did not see a single Arabica tree. It was a majority of Liberica with one or two Robustas in the mix, and some hybrids between the two. The farmers couldn't tell them apart.

The Liberica coffee cherries in this area come in various shapes and colours, some we have not even seen before. Apart from the usual large oval Liberica cherries, there are ones that are slightly flat and pointy, olive-like, and elongated. Some trees have small and densely-packed cherry clusters, which may be a hybrid of Liberica and Canephora according to Jackz. For cherry colours, there were red, pink, yellow, orange, purple, and some in-betweens.

The three that stood out to us were the two purple Liberica varieties that came in large and small cherry sizes and a yellow pointy olive-like Liberica variant.

We suggested the farmers try harvesting and processing these varieties separately. Compare their weight loss percentage after removing the pulp and mucilage from each cherry, and see if there is any difference between the traditional Liberica, which has a seed yield rate of about 7% (the seed is the coffee bean), and these newly discovered varieties.

Compared with the 25% yield rate of Arabica, the 7% yield rate of Liberica has been a nightmare for this variety since its discovery. I have read in reports that a certain Liberica variety can have a seed yield rate of up to 11%. Excelsa, a suspected variant of Liberica, is said to have similar properties, so these classification experiments are necessary for understanding these different varieties.

In addition, Jackz also suggested that farmers plant these "abnormal" plants in separate areas. This not only makes it convenient for farmers to pick and process uniformly but also allows for more detailed classification in product descriptions in the future, thereby increasing the selling price. Imagine which would sound more attractive: a dark purple Liberica from Sarawak Highlands, or, a general Liberica?

Talking about the advice Jackz gave on this trip, it can only be said that coffee farmers in Long Banga are fortunate. I originally only intended to share with the farmers:

1. Basic reinforcement of seedlings' root system

2. Main pruning techniques

3. Optimisation of planting arrangement

4. Drying treatment

5. Defect bean classification

6. Annual production and expenditure budget analysis

I thought the main goal was to ensure the production of qualified beans so that the purchasing line can take shape.

Stepping into these coffee plantations, Jackz, who has farming experience, immediately clicked with the locals and started sharing with little pauses in between. His immense passion for coffee cultivation is apparent. Furthermore, because Jackz could speak the local language fluently and was willing to share his valuable experiences selflessly, he answered all questions with ease. Many local coffee farmers exclaimed, "We hit the jackpot!"

During our coffee knowledge-sharing session with the Long Banga coffee farmers, we were lucky to have Jackz assist with translation and provide many supplementary insights to facilitate the smooth delivery of knowledge. He also shared many planting suggestions that were worth reference for coffee farmers. We are very grateful.

Most of the coffee farmers we encountered during our visits to various coffee plantations seemed somewhat helpless. Many of the plantations were in a semi-abandoned state, with the coffee trees not being well-maintained, and the coffee cherries were not harvested. Some plantations had coffee trees that were not growing well and required stumping to rejuvenate the trees before they could improve.

However, there were also several good plantations located near the village, and most of the coffee trees bore abundant fruits. It was said that there were originally more than fifteen coffee plantations around the area, each with over 1200 coffee trees, but most of them have only about 600 to 800 trees left due to the lack of buyers and poor management. Now, less than a handful of farmers own more than a thousand coffee trees.

Long Banga's Liberica coffee was planted on both plains and slopes. The plantations in the mountains exhibited the same problems as the coffee plantations we had seen in other parts of Malaysia. The coffee plants were arranged vertically, similar to pepper cultivation. The problem with this arrangement was that every time it rains, water flows straight down and washes away nutrients from the soil, resulting in a loss of moisture and fertiliser. This is critically inefficient.

The more reasonable approach would be to arrange the coffee plants horizontally, in a similar manner to terraced fields, from the top of the slope to the bottom. The coffee trees on the upper and lower rows should be staggered so that the water draws from top to bottom in a sinuous flow. This not only helps to retain water better but also allows the nutrients from the upper row of coffee trees to be transmitted layer-by-layer downwards, reducing fertiliser wastage.

Another obvious issue is road accessibility. It was difficult to travel from plantation to plantation with all the muddy and slippery paths along the way. We had only managed to visit four in a day though we had a four-wheel drive.

Under such circumstances, coffee farmers do not have their own de-pulping machines in their farms to process coffee cherries into parchment coffee. it would be difficult for them to carry heavy sacks of cherries back and forth between farms and the village centre for immediate processing. This may explain why most of the samples we collected along the way had a strong mouldy odour. Almost 90% of the coffee beans they had shown us were mouldy and pale, as well as off-tastes caused by over-fermentation.

Liberica has higher sugar content. If it is not processed immediately after being harvested, deterioration happens faster than usual. Thus, delayed processing and insufficient drying are the primary issues that need to be addressed in Long Banga.

As for how to obtain de-pulping machines and hullers, I have a plan in mind. Based on the memorandum of understanding (MOU) signed between Earthlings Coffee and the Department of Agriculture (DOA), I ought to submit a joint petition letter from the villagers to the DOA or FAMA.

As it turned out, just two days later, we received a verbal confirmation from the director of FAMA in Sarawak at his office that they would provide several machines, including a pulp remover and a huller, to Long Banga. As for the humidity problem, I had originally planned to get a shared humidity meter, a few movable drying racks, and a dryer for the villagers to use. However, Jackz offered another suggestion: to fund simple greenhouse structures for the coffee farmers. I thought it was a great idea, especially if we could add a ventilation system.

On our last night in Long Banga, the villagers hosted a farewell party for us, during which I shared our new strategies with the coffee farmers:

1. Introduce proper processing, drying, hand sorting, and moisture-proof packaging to improve the quality of their existing coffee.

2. Earthlings Coffee will sponsor several coffee farmers who had already achieved mass production with greenhouses, drying racks and basic ventilation systems.

3. We proposed two simple harvest grades for coffee farmers to understand: C grade for beans with no visible defects, and B grade for beans with no visible defects and no mouldy odour. We promised to purchase C and B-grade Liberica coffee from the coffee farmers at a constant base price. As long as their coffee meets C-grade quality or higher, we will buy it. Additionally, we will also buy from these coffee farmers dried coffee husks (Cascara) and coffee blossoms to provide them with additional income.

4. We offered to appoint Alasdair as Earthlings' direct-trade green coffee buyer who will also oversee quality control and shipping issues. (Alasdair has not yet agreed to this proposal, as he seems more concerned with the coffee farmers' overall welfare than business profits).

5. There shall be no coercive binding or hidden agendas between us and the Long Banga coffee farmers. Anyone can freely purchase their coffee at a better price. If we happen to like a particular coffee, it shall enter into the principle of free market price competition (yes, I am a staunch believer in Friedrich Hayek's free-market economics).

I think the issue of Sarawak coffee cultivation is very complex and can only be successfully addressed through the comprehensive strategies listed above. This also aligns with the principles of the MOU we have with Lawas Coffee Estate, in which we fully support the production of high-quality Arabica coffee in Lawas Highlands and promised to purchase at a higher price if they can produce more volume. We also impose no trade restrictions, if other parties are willing to buy from them at a higher price, they are free to do so. I believe this kind of relationship will be truly mutually beneficial.

I hope that in a few months, Long Banga will be able to produce better-quality Liberica coffee. Having to achieve baseline-quality coffee, we can then move on to more advanced knowledge sharing on fine quality improvement.

In my opinion, the journey to successful coffee cultivation in Sarawak will be a rough one. Most coffee farmers lack the relevant knowledge (though they may be experienced farmers), land transportation is inconvenient, soil fertility is inadequate, high-elevation farmland is rare, and global warming presents an increasing challenge to growing conditions.

It will be difficult to position Sarawak coffees in the low-price commercial market, we don't stand a chance against countries like Brazil, Vietnam, Indonesia, and India in terms of cost-effectiveness. If we want to compete in quality Arabica, the low elevation proves to be a challenge.

If we could not develop alternative strategies to create a more wholesome economic chain from crop to cup, local coffee cultivation may be difficult to achieve new heights. Therefore, in the long run, I believe that focusing on refining Liberica and Canephora coffee, as well as hybrid Arabica, are the more sustainable options for Sarawak.